In a world where precision meets creativity, CNC programming stands out as the secret sauce behind modern manufacturing. Imagine a machine that can turn your wildest designs into reality, all while you sip your coffee and watch. It’s not magic; it’s CNC programming, and it’s the key to unlocking a treasure trove of career opportunities.

Taking a CNC programming course is like getting a backstage pass to the concert of technology. Whether you’re a seasoned pro or just starting out, this course will equip you with the skills to command machines that would make even the most sophisticated robots jealous. Plus, who wouldn’t want to impress friends with tales of turning raw materials into masterpieces? Dive in and discover how CNC programming can transform not just materials, but your entire career trajectory.

CNC Programming Course

A CNC programming course covers the essential principles and practices necessary for operating CNC machines effectively. Participants learn to interpret technical drawings and convert them into machine instructions. Skills developed in the course include programming languages such as G-code and M-code, which are crucial for controlling machine operations.

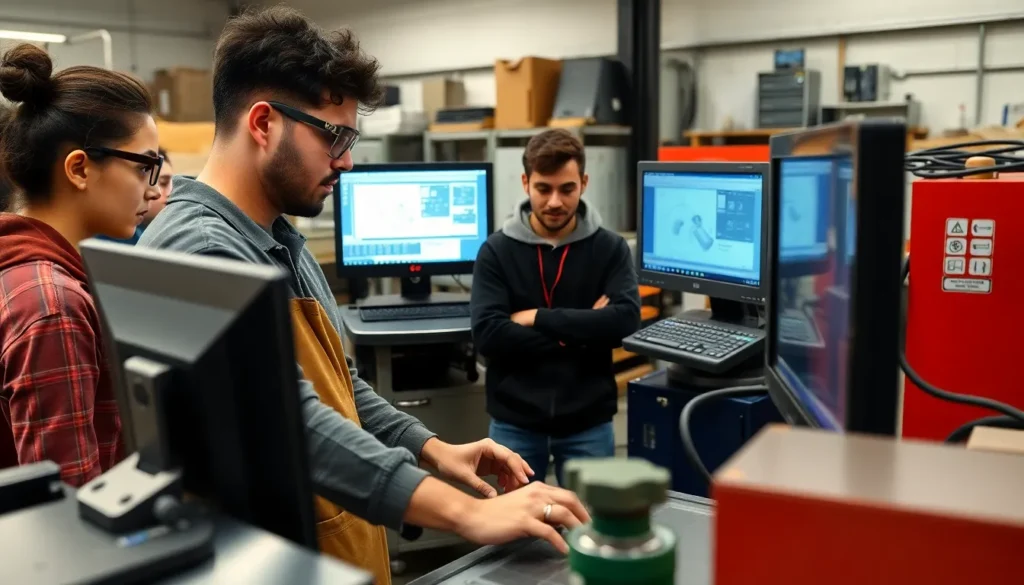

Training typically includes hands-on experience with CNC equipment, allowing learners to familiarize themselves with the machinery in a practical setting. Courses often emphasize safety protocols to ensure participants understand how to operate CNC machines without hazards. Understanding different types of CNC machines, such as mills and lathes, forms a vital part of the curriculum.

Classes may include various learning modalities, such as lectures, simulations, and lab work. Assessment methods often encompass practical projects, quizzes, and written exams, evaluating students on their mastery of course content. Access to specialized software tools for CNC programming enhances the learning journey by providing real-world applications.

Career opportunities upon course completion can include roles such as CNC programmer, machinist, and manufacturing technician. Graduates are well-prepared for various industries, including automotive, aerospace, and manufacturing sectors. Enrolling in a CNC programming course positions individuals to take part in high-demand fields, equipping them with skills relevant in today’s job market. The increasing reliance on technology in production further boosts the value of CNC programming abilities.

Overall, a CNC programming course offers a comprehensive foundation that supports practical application and career advancement in the manufacturing domain.

Benefits of Taking a CNC Programming Course

Taking a CNC programming course offers numerous advantages that enhance professional capabilities.

Skill Development

CNC programming courses focus on vital skills required for operating advanced machinery. Students gain knowledge in translating technical drawings into machine instructions. Individuals learn programming languages like G-code and M-code, which are essential for CNC operations. Hands-on experience with various CNC equipment reinforces learning. Instructors emphasize safety protocols while familiarizing students with different machine types. Each component builds a comprehensive skill set that prepares students for real-world applications. Mastery of these skills helps students excel in manufacturing and engineering environments.

Career Opportunities

Opportunities in CNC programming are vast and varied across multiple industries. Graduates can pursue careers as CNC programmers, machinists, or manufacturing technicians. Entry into sectors like automotive, aerospace, and electronics presents many possibilities. Demand for skilled CNC professionals continues to grow as technology advances. Many employers seek candidates with strong programming backgrounds and practical experience. With the training received, individuals can easily transition into roles that require precision and innovation. Career growth usually leads to higher salaries and increased responsibilities, making this field appealing for aspiring professionals.

Course Content and Structure

CNC programming courses cover a comprehensive array of topics essential for mastering the field. Students explore fundamental principles such as CNC machine operation, programming techniques, and safety protocols. Understanding technical drawings represents a crucial skill as learners translate these into precise machine instructions. Mastery of programming languages, including G-code and M-code, equips participants to communicate effectively with CNC equipment. Hands-on training with various machines, such as mills and lathes, enhances practical knowledge, ensuring readiness for industry challenges.

Key Topics Covered

Key topics include CNC technology basics, programming methodologies, and advanced machining processes. Programming languages form a core part of the curriculum, emphasizing both G-code and M-code usage. Safety regulations and best practices support a safe learning environment. Important concepts like tool selection and setup procedures are introduced, enabling students to perform effectively in real-world scenarios. Additionally, troubleshooting techniques cultivate problem-solving abilities, preparing graduates for diverse manufacturing contexts.

Duration and Format

Course duration typically spans several weeks, often ranging from 4 to 12 weeks, depending on the program structure. Flexibility marks the format, incorporating both in-person and online components. Mixed learning options engage students through lectures, interactive simulations, and hands-on lab experiences. Assessments consist of practical projects and written exams, reinforcing knowledge and skills. Participants often receive certification upon successful completion, validating their expertise and enhancing employability in the CNC programming field.

Choosing the Right CNC Programming Course

Selecting the appropriate CNC programming course involves careful consideration of various factors. It’s essential to explore options that align with individual learning preferences and career goals.

Online vs. In-Person Classes

Online classes offer flexibility, allowing students to balance other commitments while learning. Participants can access materials and lectures at their convenience, making it a suitable choice for those with busy schedules. In-person classes provide hands-on experience in real manufacturing environments. These sessions foster direct interaction with instructors and peers, enhancing the learning experience. Combining online and in-person formats may provide the best of both worlds, ensuring comprehensive understanding through diverse modalities.

Accreditation and Certification

Accreditation signifies that a CNC programming course meets industry standards and quality benchmarks. It guarantees that students receive a respected education, increasing employability. Certification upon course completion validates a student’s skills and knowledge, making them more competitive in the job market. Selecting an accredited program enhances career prospects, as employers often prioritize candidates from recognized institutions. Participants should verify accreditation status before enrolling, ensuring their investment pays off in future opportunities.

Student Experiences and Testimonials

Students consistently express satisfaction with their CNC programming courses. Graduates highlight the comprehensive training that includes practical applications and safety protocols. One student mentioned how the hands-on experience with CNC machines solidified their understanding of programming languages like G-code and M-code.

Feedback from participants frequently showcases their readiness for the job market after completing the course. Many students report gaining confidence in their abilities to interpret technical drawings and convert them into machine instructions. Individuals transitioning from different fields also note the ease of acquiring new skills, emphasizing the course’s effectiveness.

The supportive learning environment stands out to many learners. Instructors often provide personalized guidance, helping students grasp complex concepts more easily. Peer collaboration within in-person classes fosters camaraderie, allowing participants to share insights and experiences.

Career opportunities arise as a common theme in testimonials. Graduates commonly find roles in sectors such as automotive and aerospace, where demand for skilled CNC professionals continues to rise. Students frequently appreciate the certification received upon completion, viewing it as a valuable credential that enhances their employability.

Overall, the enthusiasm for CNC programming courses remains evident in student testimonials. Success stories abound, showcasing graduates who secured rewarding positions, leading them to fulfilling careers. Students emphasize the course’s impact on their professional journeys, paving the way for long-term growth and development in an evolving industry.

Conclusion

Enrolling in a CNC programming course can be a transformative step for anyone looking to advance their career in manufacturing. With the right training and hands-on experience, individuals can master essential programming languages and techniques that are crucial in today’s tech-driven environment.

The skills acquired through these courses not only open doors to various industries but also enhance job readiness. Graduates often find themselves equipped with the confidence and expertise needed to excel in roles such as CNC programmer and machinist.

As the demand for skilled CNC professionals continues to rise, investing in a CNC programming course is a strategic move toward a rewarding and prosperous career.